Looking out the hatchery door you feel a pressure moving toward you. There is a steady force pushing global poultry vaccination to earlier and earlier ages. Like an ocean tide, this flow persistently and irresistibly shifts a higher proportion of vaccinations toward hatcheries. Newcastle Disease (ND) vaccination is one being impacted.

ND virus, with its highly-contagious nature, affects all of the important commercial poultry species. It is endemic in many countries and is being battled worldwide. International trade barriers resulting from ND prevalence is a threat. Guarding birds from airborne ND virus, direct contact, and even contaminated hatchery shells is important; and the earlier the better. Some key reasons for earlier spray vaccination ages are:

• Birds with faster-growing genetics do not have as much time to develop immunity under traditional vaccination programs.

• Live ND vaccine in day-old chicks builds defenses very quickly. Local respiratory immunity rapidly appears within 4 hours following vaccination in day-old chicks, offering crucial early protection while priming antibody production for longer-lasting defense.

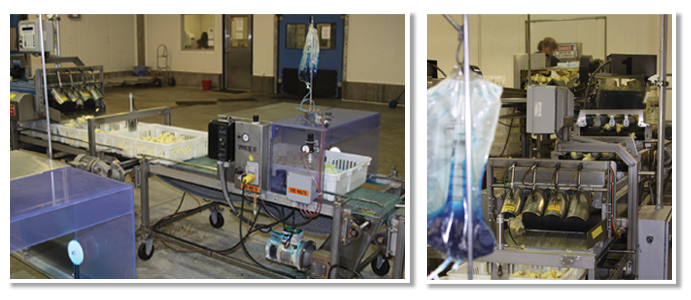

•Simple, inexpensive and accurate spraying equipment for hatcheries make vaccination more convenient and dependable, compared to time-consuming and inconsistently-applied grower vaccinations.

• Fast-growing poultry companies find it easier and safer to train and manage hatchery vaccinations than growing-house vaccinations. Independent growers that buy day-old-chicks press their commercial hatcheries to supply birds with their immune systems already stimulated and their defenses against prevalent diseases like ND under development.

Live antigens in spray vaccines must completely survive in order to provide the fullest immunity. Early vaccine manufacturers recommended that, if hatcheries planned to spray the live vaccine, they use distilled water. This recommendation came about because the vaccine manufacturers lacked the ability to manage tap water quality throughout their global customer base. Vaccines perform best when they are shielded against tap water containing natural or added oxidizing mineral elements, inappropriate pH and unbalanced electrolyte concentrations. Modern, new-generation vaccine stabilizers are designed to counteract these risks, rescuing vaccines so hatcheries can conveniently and safely vaccinate with local water sources instead of costly and cumbersome bottled water. New stabilizer technologies nurture vaccines in local tap water, make spraying more convenient and efficient, and reduce the logistics of sourcing and storing bottled water. They also reduce the plastic containers that must be disposed or recycled. Carbon-footprint-conscious poultry companies are taking note, eliminating distilled water as part of their “green initiatives.”

Earlier research in Lasher Associates’ lab confirmed the protective effect Spray-Vac® had on a fragile bronchitis vaccine. Now a more recent report describes research to learn if the new-generation vaccine stabilizer also rescues a live ND vaccine in water with high oxidative potential.

For the full article and results, click here to download the complete PDF.